AC NEWENERGY provides battery cell technology standards for various application scenarios

Cell manufacturers strictly produce according to the requirements of Acheng

AC NEWENERGY provides battery cell technology standards for various application scenarios

Cell manufacturers strictly produce according to the requirements of Acheng

The quality control team is stationed at the factory to supervise the entire production process of battery cells

Full process digital traceability to ensure the safety and reliability of battery cells

Having one of the few domestically owned high standard laboratory testing and certification capabilities

From the source technology to ensure the safety of battery cells

Cell selection, performance mining, residual value evaluation

Based on product requirements, improve testing and evaluation methods, explore battery characteristics, obtain accurate and reliable design parameters, and combine years of engineering application experience to develop control strategies that meet customer needs.

Establish a battery life value evaluation system, conduct in-depth battery selection value evaluation for different application scenarios, covering basic physical, electrochemical performance, lifespan, and safety aspects.

Evaluate battery performance through a series of standardised tests such as cycle life and charge/discharge efficiency

Extreme conditions such as over-charging, over-discharging and short-circuiting are tested on the battery cells to ensure their safety in various situations

Simulate different temperatures, humidity and other environmental conditions to test the stability and adaptability of the battery cell to ensure its reliability in a variety of environments

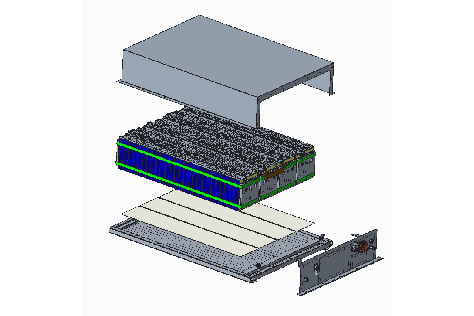

Good reliability and load-bearing capacity

Good surface smoothness and good heat exchange effect

Reduce the design of supporting structural components

Reduce weight and overall costs

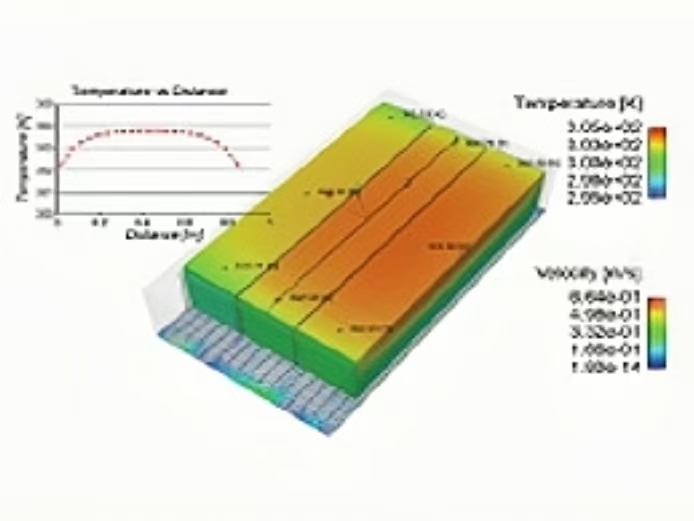

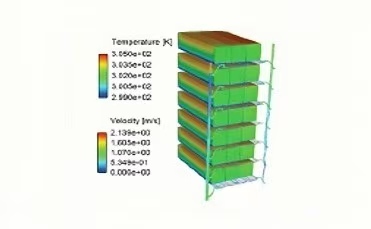

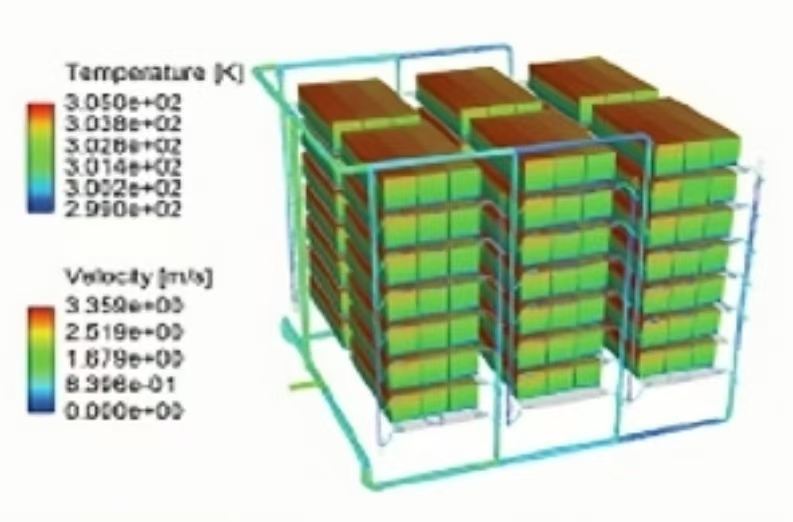

Through machine learning algorithms to autonomously adjust the control logic to adapt to dynamic changes in the environment and complexity, to achieve the optimal temperature range to ensure stable and long-lasting performance.

By real-time monitoring of the cold plate surface and connecting piping for liquid leaks, problems can be quickly detected, giving early warning and significantly improving the stability and reliability of the system.

New balanced runner design

Cold plate temperature difference controlled within 1.5°C

Temperature field uniformity improved

Parameter measurement - precise sampling

Algorithm Strategy - Accurate Prediction of SOC and SOH

Thermal management - intelligent liquid cooling, low consumption, long service life

Fault diagnosis - self inspection, self diagnosis, self recovery

Security protection - multiple protection against threshold and change threshold

Big data - real-time synchronized cell level monitoring

Chips and wireless communication

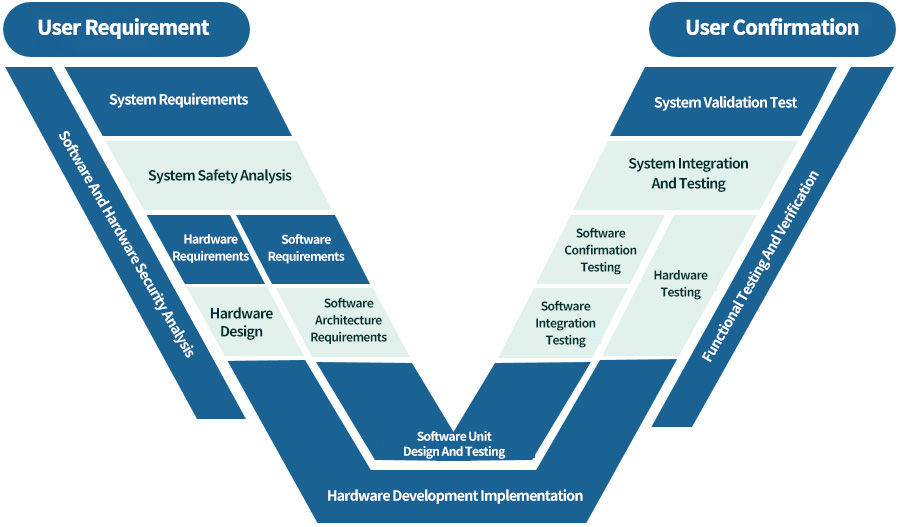

Cell testing, screening: including safety performance, capacity, cycle life, internal resistance.

BMS performance testing: including DC supply voltage testing, overvoltage testing, superimposed AC voltage, reset characteristics, start-up characteristics, short-circuit protection, etc.

PCS performance testing: including power conversion efficiency, voltage and current ranges, harmonic distortion, power factor, vibration and shock testing, etc.

Management Review Control, Supplier Development, Supplier Control, Production Equipment Management Control, Monitoring and Measuring Device Control, Inspection Control, Nonconforming Product Control, Material Recognition Management, Process Abnormality Handling, Shutdown and Rework Management, Special Purchase Management, Rework Management, etc.

Module testing: including voltage, DCIR, etc.

Pack testing: including safety testing, air tightness testing, ATE testing, etc.

Battery cluster testing: including aging testing

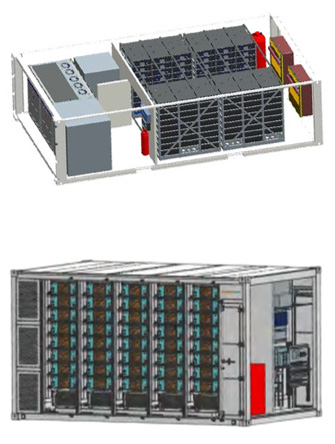

Container testing: including safety testing, liquid cooling testing, container performance testing, etc.

The battery pack is equipped with a three-in-one detector, and the cabin is equipped with smoke, temperature and combustible gas detectors, which can sense the signals before the thermal runaway of the electric cell in advance and provide intelligent warning.

Adopting the total flooding fire extinguishing programme, it can accurately achieve the package level, cluster level and cabin level fire extinguishing, in addition to setting up independent water flooding fire extinguishing, and continuously cooling down the energy storage compartments.

The alarm can cut off the AC and DC power supply in time, issue sound and light alarm signals, and upload the signals to the central control room.

Historical data and real-time monitoring

Platform can provide recommendations for performance optimisation

Helps improve efficiency of energy storage systems

Fault Warning System

Platform with intelligent analytics

Ability to provide early warning of potential equipment failure

Reduced system downtime

Performance Optimisation Recommendations

Based on historical data and real-time monitoring

The platform can provide recommendations for performance optimisation

Helps improve the efficiency of energy storage systems

Intelligent centralized control center

Power station distribution; Power station status; Electricity generation statistics; Revenue statistics;

Real time warning; Accurate positioning; Diagnostic analysis; Data analysis;

Intelligent management of devices

Monitoring hidden dangers

Accurate alarm location and cause, quick detection of power plant issues

Electricity consumption must be contested

Timely maintenance by the power station team to improve maintenance efficiency

State of Health (SOH) assessment;

Remaining useful life (RUL) prediction;

Economic value assessment;

Cost assessment of recycling and remanufacturing;

Separate positive and negative electrodes through special equipment

Independent materials such as shells.

High power applications: low-speed special vehicles;

Medium power applications: backup power sources, industrial equipment, etc;

Low power applications: portable devices, small electronic devices, lighting, etc;

Obtaining controllable positive and negative electrode materials through various environmentally friendly processes,

Once again, advanced technology has been used to make the materials ready for direct use.