100% inspection of integrated box body;

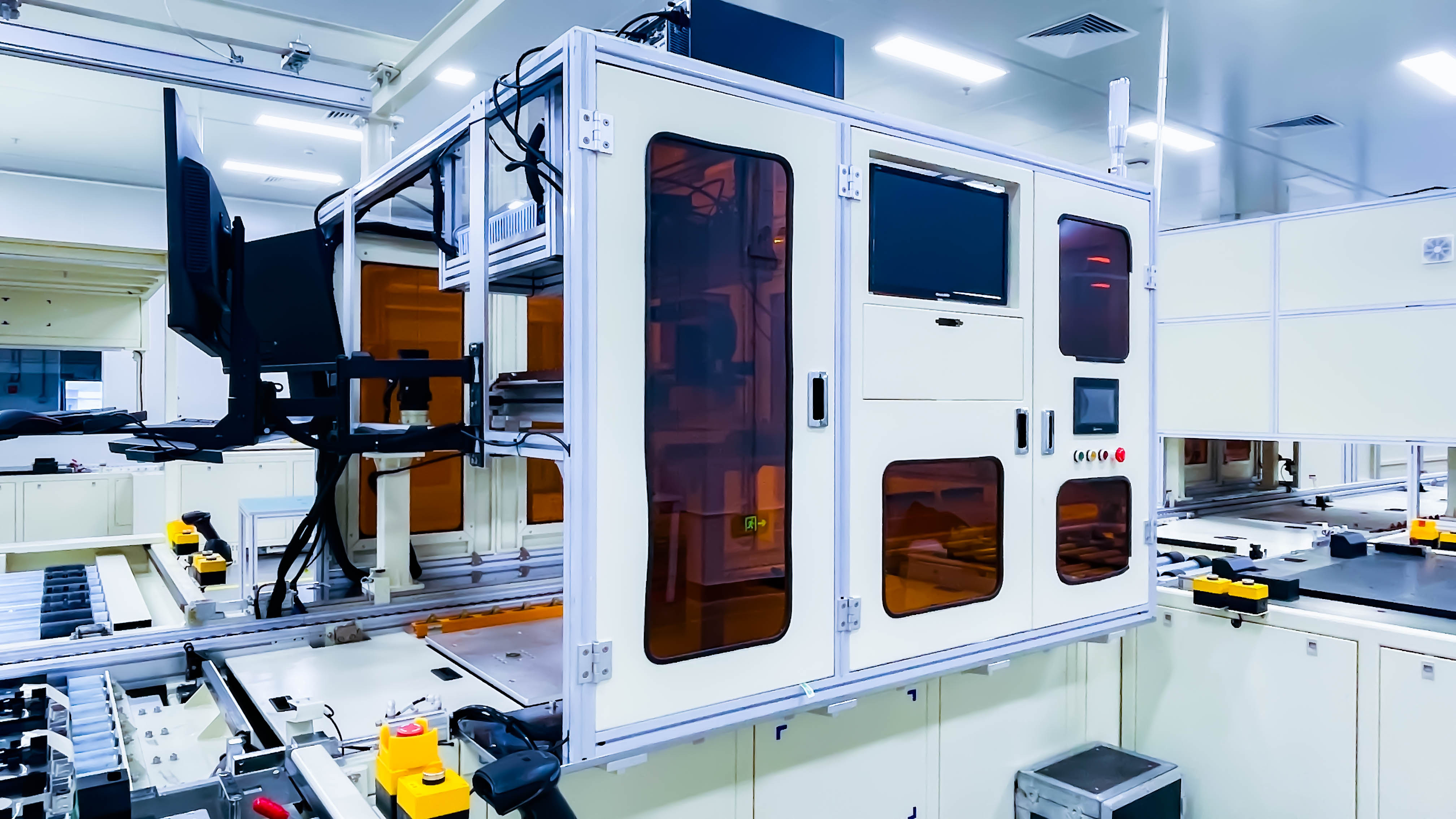

IPX5 level automatic sprinkler equipment ensures reliable water leakage testing of the box body;

Film thickness/color difference inspection to ensure consistency of cabinet appearance;

System basic environment construction

System high availability

Information system integration

Data archiving strategy

Production progress monitoring

Production anomaly monitoring

Enterprise Management Operations Center

Full traceability information

Quality monitoring dashboard

Production monitoring dashboard

Plan execution follow-up dashboard

Production execution process control

Work in progress management

Production Execution Analysis

Production quality analysis

Packaging management

Basic equipment information

Equipment operation status

Equipment maintenance and upkeep

Production online quality monitoring

Production quality monitoring

Compliance management

Key Processes

Key Capabilities

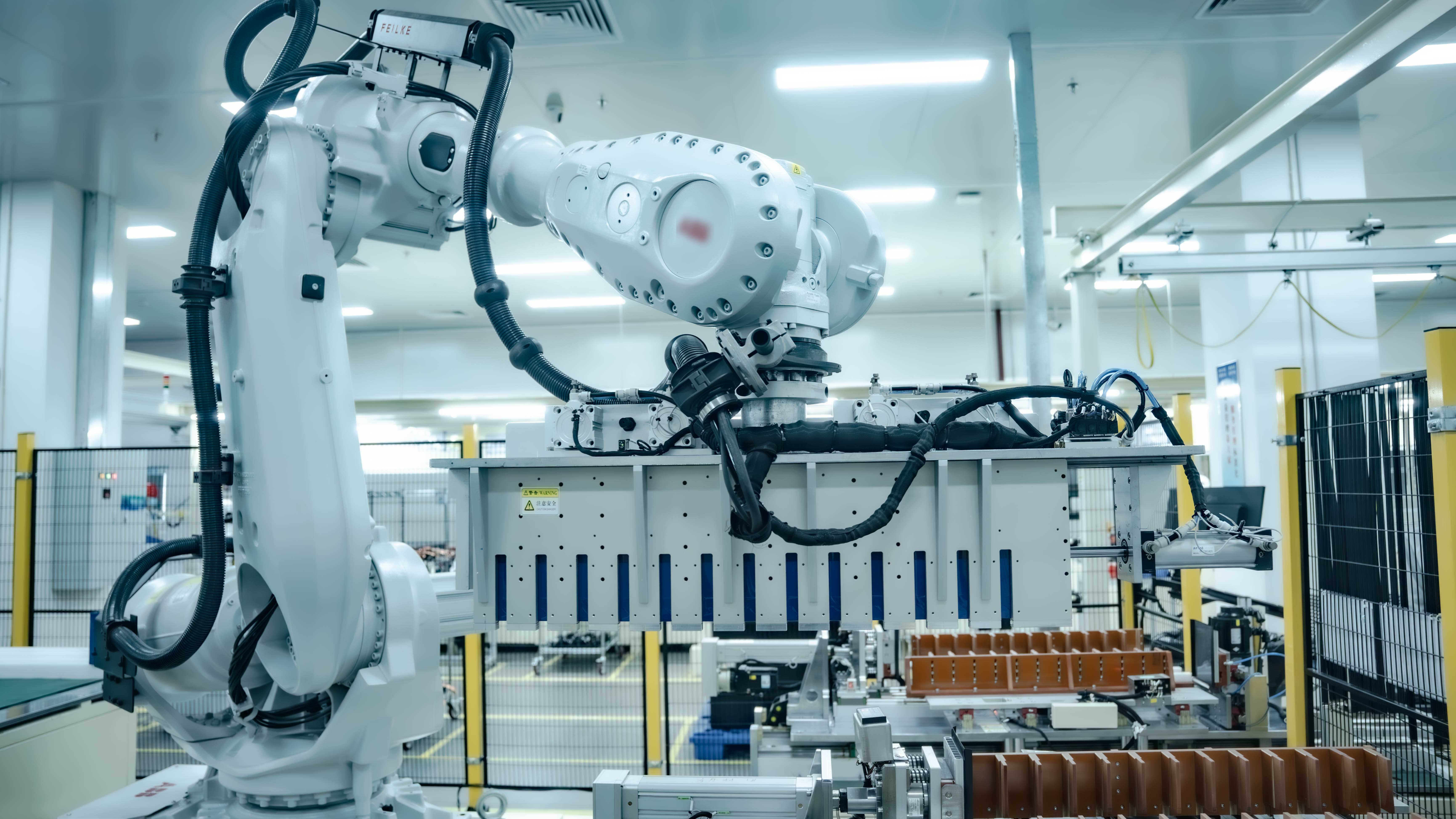

Robot feeding;

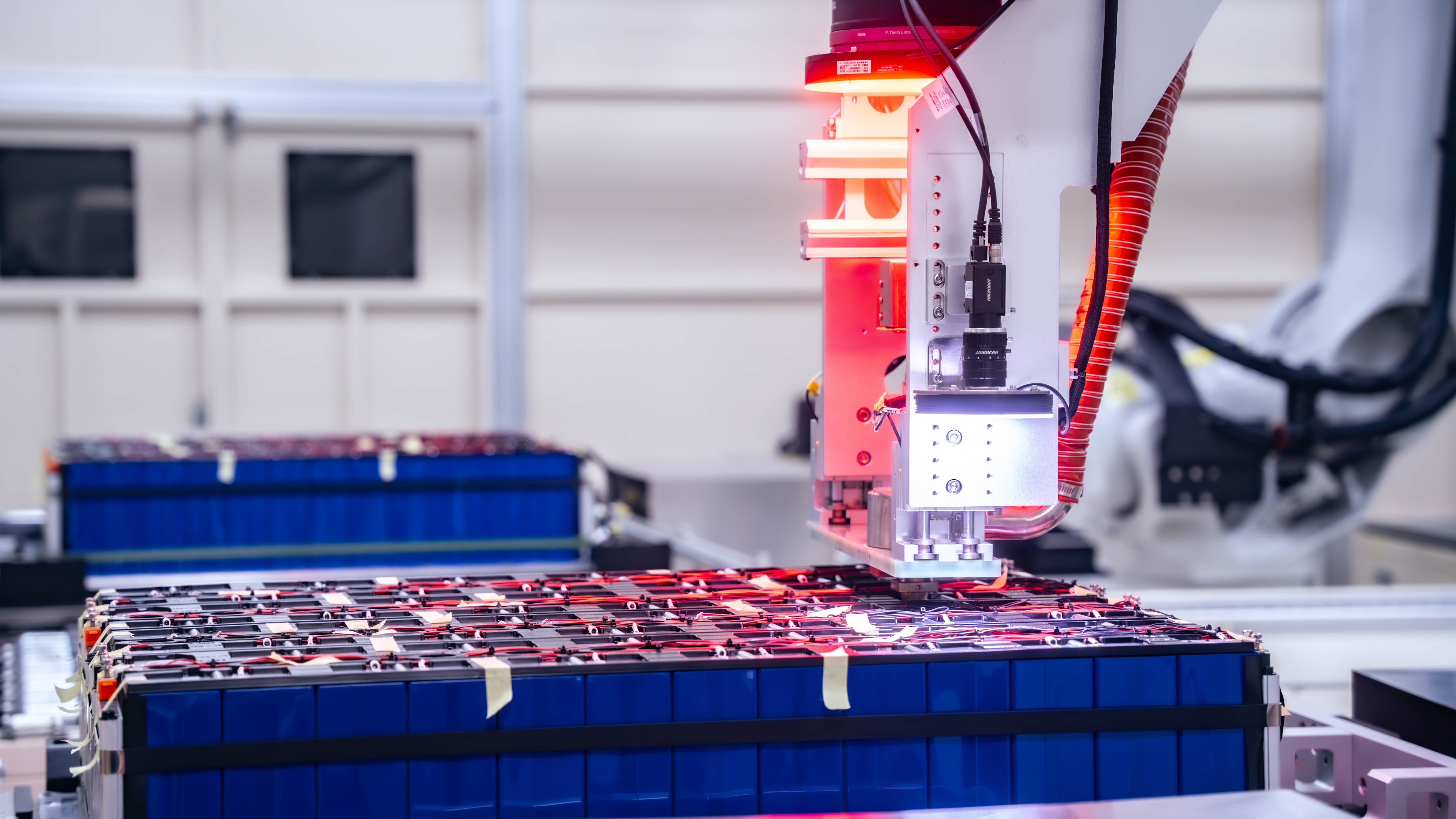

100% Voltage / internal resistance / K value / thickness , blue film inspection;

130-150KHZ high-frequency laser cleaning;

Robot duplex fully automatic stacking;

Stacking accuracy range 0.2mm;

Pressure control range 300kg-500kg;

12 million high-definition CCD positioning;

Positioning accuracy ± 0.1mm;

The missed judgment rate is 0;

Robot welding;

Advanced circular spot welding technology in the industry;

Welding DOE;

SPC control for melting depth and melting width;

12 million high-definition CCD detection;

Detection accuracy ± 0.1mm;

The missed judgment rate is 0;

Intelligent electric batch data upload to MES system;

Torque batch secondary recheck;

Single cell voltage test;

Overall voltage testing;

Safety testing;

Temperature difference control;

100% aging;

0.0005A testing accuracy;

DCIR integration testing;

100% inspection of integrated box body;

IPX5 level automatic sprinkler equipment ensures reliable water leakage testing of the box body;

Film thickness/color difference inspection to ensure consistency of cabinet appearance;

Dedicated high-efficiency battery pack shelving and stacking vehicle;

Key process: Rexroth Nexo wireless Wi Fi tightening;

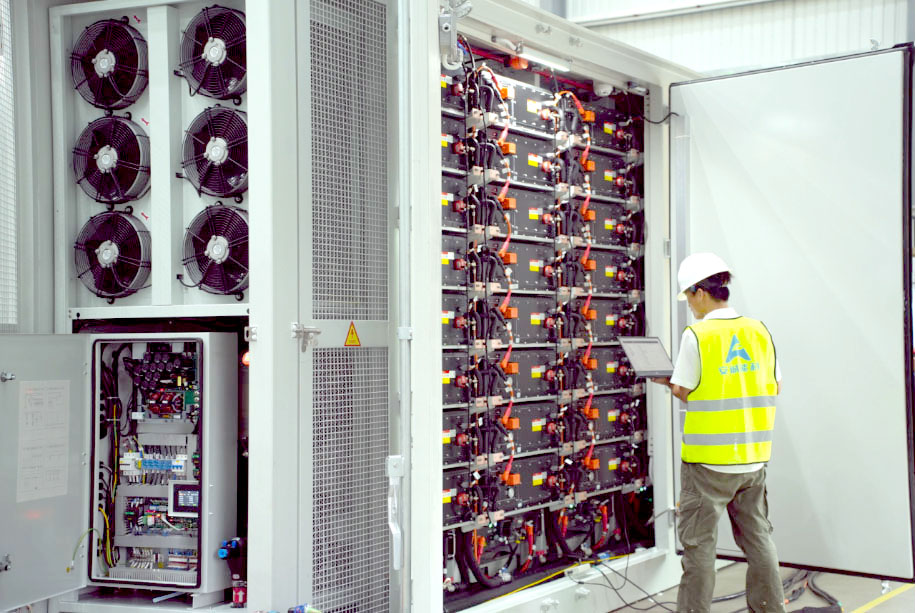

Configure an integrated debugging platform;

Power grid simulator;

Maximum current 710A

Distribution capacity 426KVA;

100% debugging of power/communication/liquid cooling/fire protection systems;

63T driving covers the entire area;

3T/5T electric forklifts can flexibly cooperate with daily operations;

Special lifting equipment for lifting and loading onto vehicles, safe and efficient;